Technical Specifications of the Plastic Granule Centrifuge Dryer

Centrifuges generally operate at high speeds, and balancing these units is a highly complex process. The blade geometry and the calculation of their thickness—so that they can both withstand the impact of granules and effectively separate water—are among the most critical factors in their design. Furthermore, the appropriate thickness and angle of the blades help reduce wear, increase the machine’s lifespan, and lower energy consumption compared to foreign competitors.

Proper design and positioning of the blades prevent granule particles from becoming trapped between them. The use of non-magnetic 304 stainless steel sheets is essential for achieving better quality and extending the service life of the machine. It should be noted that all components must be made from stainless steel to prevent corrosion. Additionally, proper sealing of the bearings beneath the centrifuge is of great importance.

Advantages:

- Better washing performance and enhanced removal of material impurities

- Very low machine wear

- Low noise during operation

- Up to 95% dewatering efficiency

Dimensions

85 × 124 cm – Height: 220 cm

Main Motor

5.5–7.5 HP / 2500 RPM

Production Output Capacity

500-1000Kg/Hr

One of the important considerations in the plastics industry is the absence of moisture in the final products. Products that are cooled using water—such as those processed by water ring systems, underwater cutters, and water-cooled strand pelletizers—reach the end of the production line in a wet condition. This moisture must be removed quickly and to a high degree, as it can cause polymer degradation (a reduction in the molecular weight of polymer chains). To address this issue, a centrifuge is required.

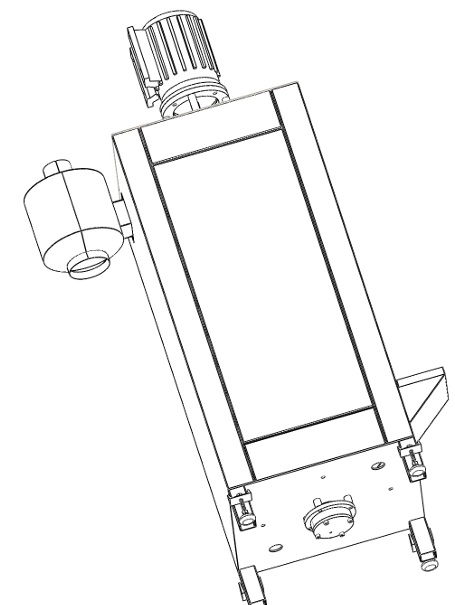

A material drying centrifuge consists of a motor, a drum or wall, rotating blades, a mesh for liquid separation, and a material outlet. This device essentially works like a washing machine, completely drying the water present in the granules. In most material drying centrifuges, the movement of granules inside the structure is from bottom to top, with the rotating shaft pushing the granules upward and dewatering them. In some centrifuges, this process may occur horizontally; however, to maximize dewatering efficiency and utilize gravitational force, the device is mainly built vertically. The water extracted by the drying centrifuge is discharged via an auxiliary motor.